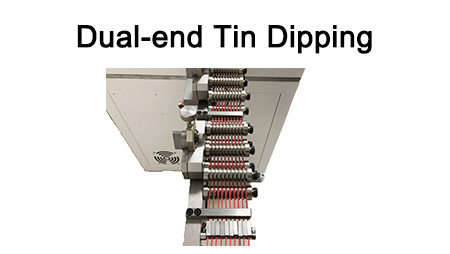

JCW-CST13 Automatic Servo Motorized Wire Stripping Tinning Machine

High-level model for precise wire stripping and soldering

Feature of the machine

The JCW-CST13 is a response to the growing needs of the rapidly evolving digital consumer electronics industry. This highly efficient automatic 8 wires crimping and soldering machine serves various applications: wire cutting and stripping, wire twisting, fluxing and tinning. The JCW-CST13's processing capacity is reaching 6600 to 14000 pieces per hour. The standard model offers 850mm cutting length, 1200mm-1500mm-1800mm are all optional. The compact machine design provides economic flexibility and high productivity.

High-quality processing and simple operation

The JCW-CST13 integrates high-quality components: 6 sets of MITSUBISHI servo motors, THK/TBI guide, FESTO valve, highly rigid transmission structure, high-speed control system. Super user-friendly interface and 7" touch screen interface offer accurate input and clear vision. A motorized digital wire twisting monitor brings perfect wire tinning. Vivid detectors ensure high-quality production: wire lack detection, wire knot detection, stripping detection, air pressure detection, etc.

Various options and peripherals

- Ultrafine wire AWG 32

- Ultra short processing 8 mm

- 1200mm / 1500mm / 1800mm cutting length

- Wire prefeeder for keeping proper wire tension

- Conveyor belt for stacking finished wire

- Customize HMI, language & logo

![Single-end Automatic Wire Cut Strip Crimp Machine [ Twist on request ]](/data/thumb/res/en/20210828/71b1edefe32535b4.jpg_20210828131138_800x800.jpeg)