JCW-CST07B Automatic Single-end Crimping & Single-end Tinning Machine

Reliable, robust, excellent wire twisting, lead-free tinning

Feature of the machine

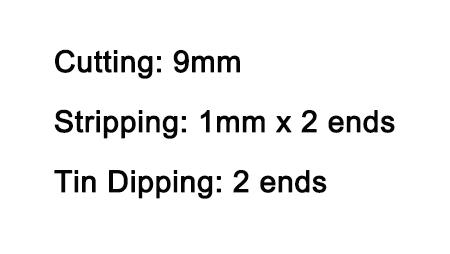

The JCW-CST07B is a highly reliable automatic crimping machine with 4 processing stations, serves various applications: wire cutting and stripping, terminal crimping, wire twisting, fluxing and tinning. The JCW-CST07B is designed for meeting high-quality requirements on terminal crimping and wire tinning. Crimp applicator changeover is simple and fast, both vertical and horizontal types are suitable. The specially designed twisting station offers super neat and beautiful twisting on conductor end strands, cooperate with the 90-degree dip tinning action, the JCW-CST07B brings you impeccable products.

High-quality processing and simple operation

The JCW-CST07B integrates high-quality components, Nidec servo motors, Panasonic PLC, Omron temperature control, highly rigid transmission structure, high-speed control system. Production parameters are entered with the 7" WEINVIEW touch screen monitor via the intuitive user interface to reduce training time and minimize entry errors, everyone can use it easily and quickly. The JCW-CST07B offers vivid detection functions, wire lack detection, wire knot detection, stripping detection, crimping detection, air pressure detection, etc.

Various peripherals and options

- Crimping force monitoring ( CFM )

- Wire prefeeding machine

- Conveyor belt ranging from 1 meter to 6 meters

- Various languages

![Single-end Automatic Wire Cut Strip Crimp Machine [ Twist on request ]](/data/thumb/res/en/20210828/71b1edefe32535b4.jpg_20210828131138_800x800.jpeg)