Vertical / End feed terminal

Shark teeth / 187 / 250 / O ring / Flat terminal

3 tons crimping force

Wire range AWG 32 - 14 [ 2mm² ]

PVC, Teflon, Silicone, Low halogen, Fiberglass cables

JCW-2TC END

Vertical / End feed terminal

Shark teeth / 187 / 250 / O ring / Flat terminal

3 tons crimping force

Wire range AWG 32 - 14 [ 2mm² ]

PVC, Teflon, Silicone, Low halogen, Fiberglass cables

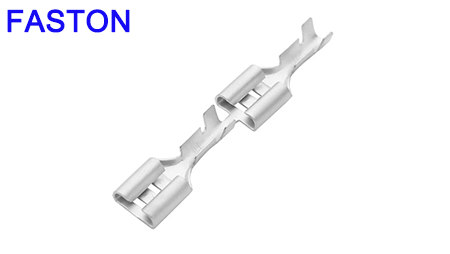

FASTON Quick Connect End-feed Terminal

FLAG Terminal

JCW-2TC-END Electronic Rear-feed Wire Strip and Crimp Machine

Stripping before crimping, precisely position wire and crimp terminal onto the wire

High precision for various end-feed terminals

The JCW-2TC-END wire strip and crimp machine is designed to process the rear-feed terminal in a roll, it's capable of stripping the wire and crimping terminal in one work step. The wire gripper holds the wire tightly and positions it above the terminal precisely, the user does not need to move the wire so to guarantee high precision. Insulation cutting accuracy and wire position accuracy are 0.05 - 1 mm.

The JCW-2TC-END strip and crimp machine apply to various end-feed terminals, such as shark teeth connector, 187, 250, O ring and flag terminals, etc.

Compact and reliable

The JCW-2TC-END wire strip and crimp machine only require a similar space as a regular semi-auto terminal crimping machine. It featured a really compact wire gripper in order to make it more approachable to the front working area.

The robust design of the whole machine and crimp applicator guarantee long service life and reliable performance. The machine speed is adjustable to suit the proficiency of the operator.

The JCW-2TC-END strip and crimp machine can be equipped with a crimp force monitor. This stripping and crimping machine is equipped with a scrap vacuum system and lighting of the working area.

| Model | JCW-2TC-END Automatic Wire Strip and Crimp Machine |

| Function | Single wire, Multiconductor cable, Wire stripping, Terminal crimping, End feed terminal |

| Raw material | PVC, Teflon, Silicone, Low halogen, Fiberglass, etc |

| Crimp force | 3 tons |

| Conductor cross-sections | 0.03 - 2 mm² [ Customizable ] |

| Stripping length | 1 - 8 mm |

| Cutting accuracy | 0.05 - 1 mm |

| Position accuracy | 0.05 - 1 mm |

| Stroke | 50 mm |

| Power supply | AC 110 - 220 V ± 10%, 50 / 60 Hz |

| Air supply | 0.5 - 0.6 MPa ( clean and dry air ) |

| Dimensions | L 460 x W 520 x H 1100 mm |

| Weight | 105 KG |

| CE-Conformity | Complies with CE equipment guidelines relative to mechanical and electrical safety and electromagnetic compatibility. |